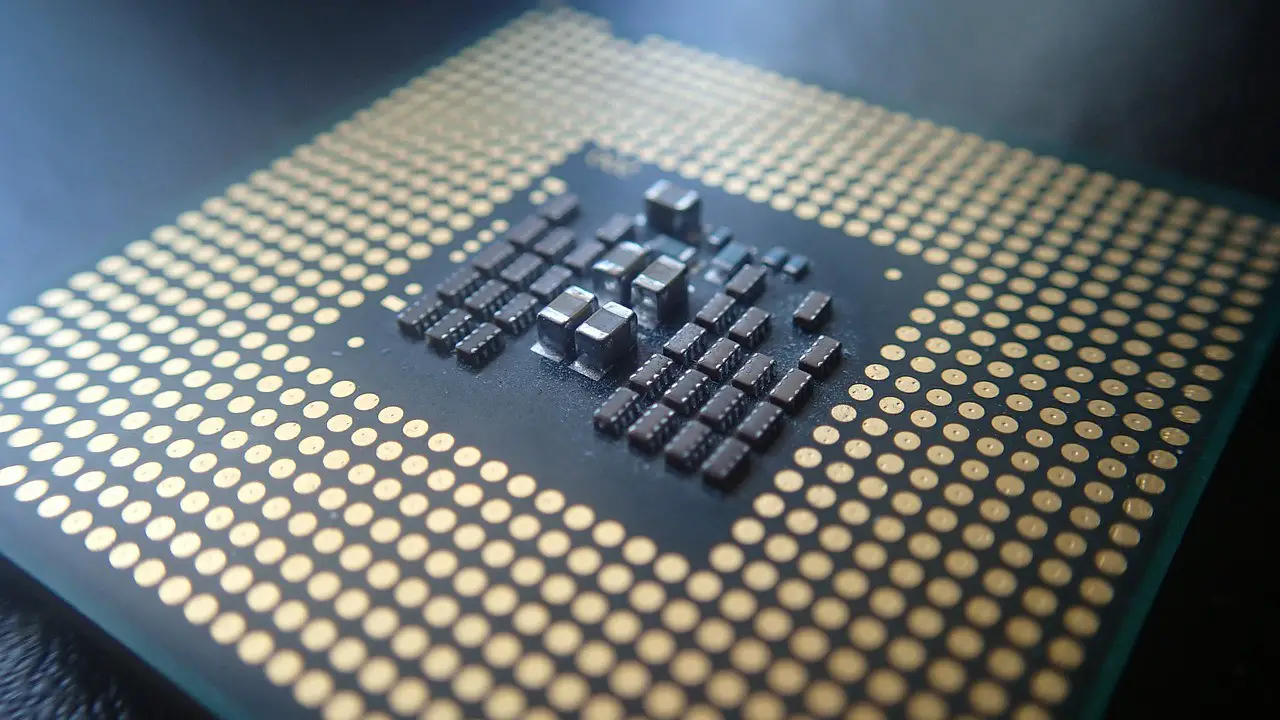

ASML, the supplier company of the major semiconductor manufacturers, predicts 1nm processors to be manufactured by 2030. Semiconductor manufacturers such as Intel, TSMC and Samsung are using advanced photolithography techniques to reduce the size of their transistors, because every nanometer they manage to reduce is a giant step.

1nm processors will be ready by 2030

Currently, 3nm transistors are already being produced, but ASML, a Dutch company that manufactures the equipment used by most semiconductor manufacturers in their foundries, has announced its plan for the first transistors below 1nm to be manufactured for the next few years. But, Intel’s CEO Pat Gelsinger has already stated that the industry should cease discussing nanometers and start talking about angstroms (Å). Angstrom is a unit of length that is usually used when referring to wavelengths and molecular distances and is equivalent to 0.1 nanometers.

New techniques to go below the nanometers are already being tested

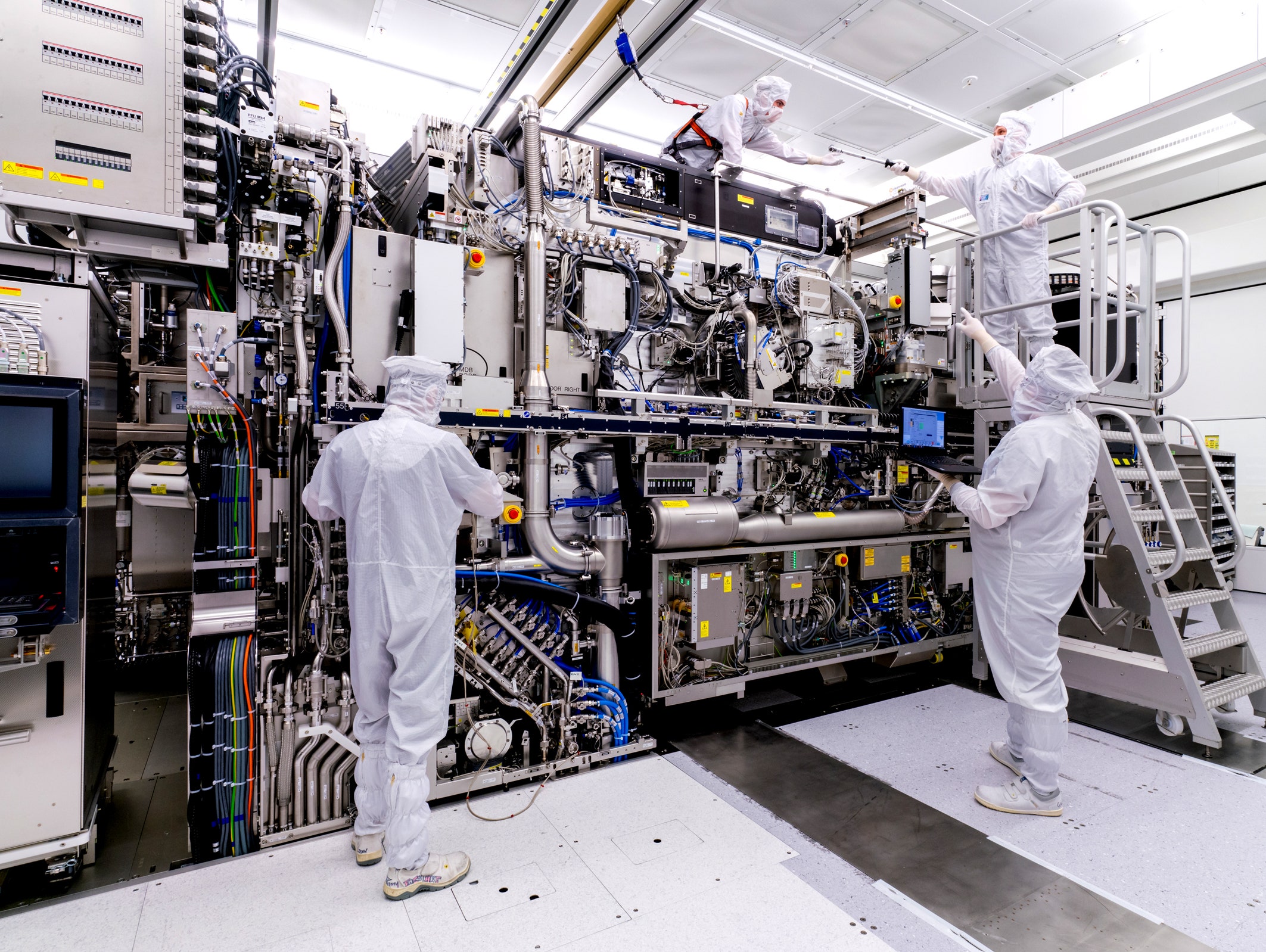

During its investor event, ASML has detailed the most relevant points of its strategy and has given a lot of details about semiconductor manufacturing processes for the next decade. According to the company, in the next few years, we will see the leap to High-NA (High Numerical Aperture) technology.

This is a platform that contains optics with a new design that can improve the resolution of the current extreme lithography platform by up to 70%. It is a machine with improved precision that will be used in the 3nm manufacturing processes, and below. By 2030, ASML expects to reduce transistor size to below the nanometer. By 2026 we would be at 1.4 nanometers (or 14 angstroms) and by 2030 we expect to reach 0.7 nanometers (or 7 angstroms).

Such small transistors will not be manufactured using the FinFET technique used by manufacturers such as Samsung. Instead, technologies such as 2D atomic channels or Complementary FET, which consists of stacking the transistors vertically, will have to be applied. By 2030, TSMC, one of the Dutch company’s major customers, plans to create processors with more than 300 billion transistors. By comparison, the NVIDIA Ampere GPU has 54 billion transistors, whereas the AMD Epyc Rome CPU based on Zen 2 and has been manufactured at 7nm and has 39 billion transistors.

End of the semiconductor crisis?

ASML estimates that the efficiency of semiconductor manufacturing will continue to improve, with an approximate 3x efficiency growth every two years, until 2040. The forecasts are optimistic and ASML expects its extreme ultraviolet (EUV) lithography machines to be ready 95% by 2025, expanding daily production capacity by more than 50%. In other words, the big company behind semiconductor production not only expects the semiconductor crisis to end, but production to double.