Reports indicate that Huawei has made significant strides in developing its own Electronic Design Automation (EDA) chip-making tools. This development is reportedly enabling the mass production of the company’s 7nm Kirin 9020 processors, a crucial step as Huawei navigates ongoing restrictions.

The move to develop indigenous EDA capabilities began several years ago, primarily to counter the impact of U.S. sanctions and to revive the production of 5G-capable Kirin chipsets for its range of devices.

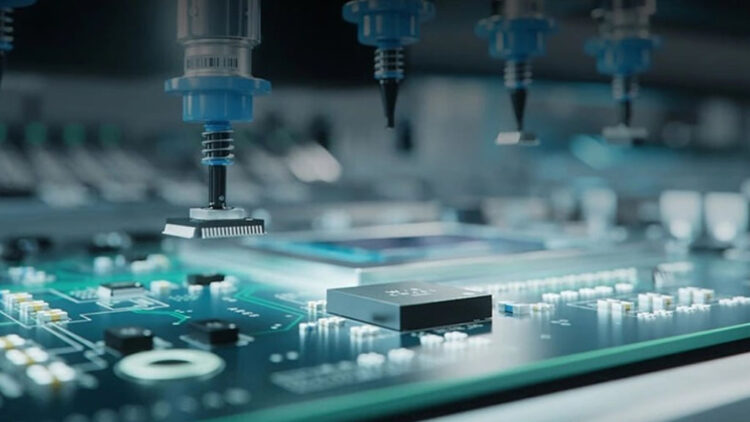

EDA is specialized software essential for the design and manufacturing of integrated circuit (IC) chips and printed circuits (PCBs). These tools are fundamental in automating and streamlining the entire chip design procedure, from initial conceptualization through verification and physical design. They are vital for handling the increasing complexity of modern semiconductor design.

According to reports, Huawei initiated collaborations with specific Chinese EDA firms as early as March 2023, initially focusing on the development of tools for 14nm chipsets. Since then, the company has reportedly advanced its technology to support the more complex 7nm process used in its latest Kirin 5G processors.

This push for domestic EDA capabilities has been bolstered by significant investment from local authorities in key Chinese cities. Municipal governments in Shanghai, Beijing, and Shenzhen have reportedly increased funding specifically for China-made EDA equipment. This financial support aims to accelerate the development of domestic chip-making tools and reduce the reliance of Chinese firms on foreign, particularly U.S., technology.

Huawei is now reportedly leveraging these domestically developed EDA tools for the mass production of its Kirin 9020 5G chipset. The Kirin 9020, first introduced last year in the Mate 70 flagship series, is currently being implemented in Huawei’s high-end Pura 80 smartphones.

While EDA machines do not directly fabricate the System-on-Chips (SoCs), they play a critical role in ensuring that chip design requirements are met, making them an indispensable component of the overall chip manufacturing process. The absence of such tools, as highlighted by an example regarding Xiaomi’s challenges with a 2nm process XRING chipset, underscores their importance.