GPTARS is an innovative project combining the power of generative AI with the iconic design of TARS, the robot from the movie Interstellar. This concept originated from Travis L‘s passion for both cutting-edge technology and cinema, particularly from the work of filmmaker Christopher Nolan.

The project’s foundation lies in the sophisticated 3D model created by Charlie Diaz, who not only designed the visual elements but also devised the movement kinematics essential for TARS’ lifelike motion. Diaz’s original guide provided a comprehensive blueprint for constructing a TARS replica, which inspired the development of GPTARS.

The journey to building GPTARS

The journey to create a functioning replica of TARS has been an extensive one, involving multiple iterations and numerous technical challenges. Initially, the focus was on replicating the physical appearance and basic movements of TARS, as depicted in Interstellar. This involved extensive use of 3D printing technology, servo motors, and a variety of electronic components. The first versions, although visually accurate, faced significant mechanical challenges, particularly in achieving stable and reliable motion.

Mechanical observations during the initial stages highlighted the complexity of TARS’ movement. Despite its seemingly simple design, TARS’ walking mechanism required intricate adjustments to ensure smooth operation. For instance, the hidden translational degree of freedom near the leg joints, which was crucial for the robot’s mobility, needed precise calibration. Early prototypes struggled with balance and weight distribution, leading to frequent mechanical failures. Over time, these issues were addressed through meticulous refinement of the design and adjustments to the walking program.

How to build your own GPTARS

Here is the complete list of parts that you need to build your own GPTARS:

Hardware components:

- Raspberry Pi 3 Model B

- myCharge Hub Mini 3350mAh/2.4A bank

- LiPo Battery (3 cell, 11.1V, 1300mAh)

- 12V to 6V DC Buck Converter

- Adafruit 16-Channel PWM Servo Driver

- Elecrow 5″ HDMI Display

- 8Bitdo Zero 2 Bluetooth Remote

- SG90 Micro-servo motor (×4)

- Metal Gear “Standard” Servo (×5)

- Machine Screw, M3

- Lightweight Actobotics Servo Horn (H25T Spline)

Software apps and online services:

- Raspbian (Operating system for Raspberry Pi)

- GPT API

Hand tools and fabrication machines:

- 3D Printer (generic)

- Soldering iron (generic)

- Solder Wire, Lead-Free

Structural components:

- 3D printed polycarbonate parts

- Aluminum extrusion “spines”

- Sheet aluminum case

- Polycarbonate screen protector

AI’s soul, TARS’ body

The true innovation of GPTARS is in the integration of generative AI, which imbues the robot with advanced conversational abilities and dynamic responses. Leveraging the capabilities of OpenAI’s GPT-4 model, GPTARS can engage in meaningful interactions, providing users with an immersive experience that goes beyond mere physical replication. This AI integration transforms TARS from a static model into an interactive entity capable of understanding and responding to a wide range of inputs.

This integration was not without its challenges. The AI needed to be seamlessly incorporated into the existing hardware framework without compromising the robot’s physical performance. The Raspberry Pi 3 Model B, used as the main computer, had to manage both the mechanical operations and the AI processing tasks. This required optimization of the software and efficient allocation of computational resources. Furthermore, ensuring reliable communication between the AI and the hardware components was crucial for achieving synchronized movements and responses.

Refining the aesthetics and functionality

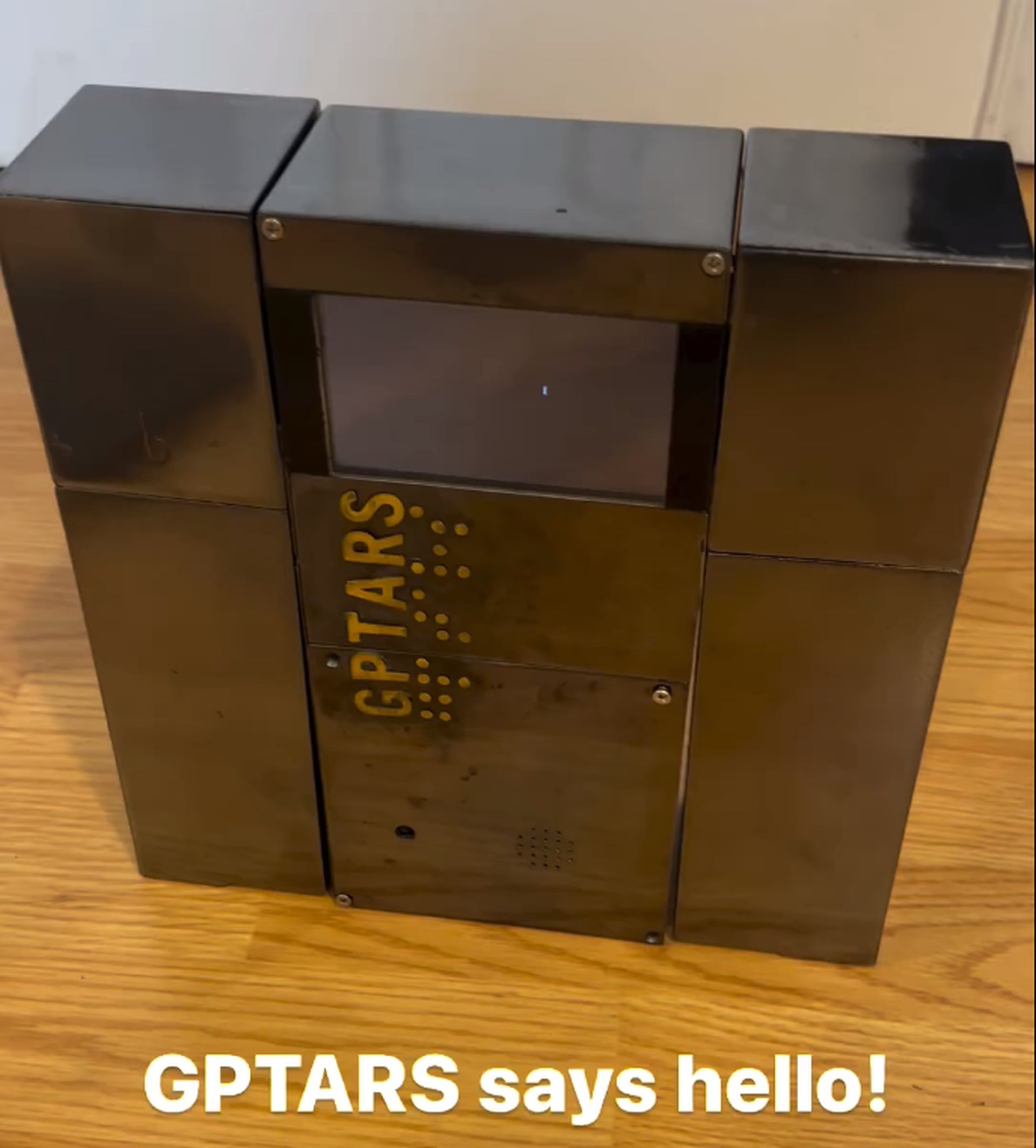

One of the significant aspects of the GPTARS project was achieving a realistic and visually appealing finish for the robot. The process of attaining a smooth, metallic look involved extensive trial and error. Numerous iterations were necessary to perfect the coating and achieve the desired aesthetic quality. This aspect of the project proved to be time-consuming, often taking longer than the programming tasks. Despite these challenges, the end result is a robot that not only functions effectively but also closely resembles its cinematic counterpart.

In addition to aesthetic considerations, functional enhancements were continually made to improve GPTARS’ capabilities. The initial versions faced issues such as heavy, unbalanced steps and frequent mechanical failures. These were gradually mitigated by optimizing the weight distribution, using lighter battery packs, and refining the walking program. The use of advanced servo motors and improved structural components also contributed to the increased reliability and performance of the robot.

The culmination of efforts

Today, GPTARS stands as a testament to the seamless integration of generative AI and robotics. The project showcases the potential of combining advanced AI models with sophisticated mechanical designs to create interactive and lifelike robots. While there are always areas for further improvement, the current version of GPTARS represents a significant achievement in both technical and aesthetic terms. As the project continues to evolve, future enhancements may include leveraging new features of upcoming AI models and further refining the robot’s physical design.

The story of GPTARS is one of relentless innovation and passion, reflecting the dedication to bringing a beloved cinematic character to life through the power of technology. The combination of generative AI with the iconic design of TARS offers a glimpse into the future of interactive robotics, where machines can not only mimic human-like movements but also engage in meaningful interactions.

Featured image credit: GPTARS/Instagram