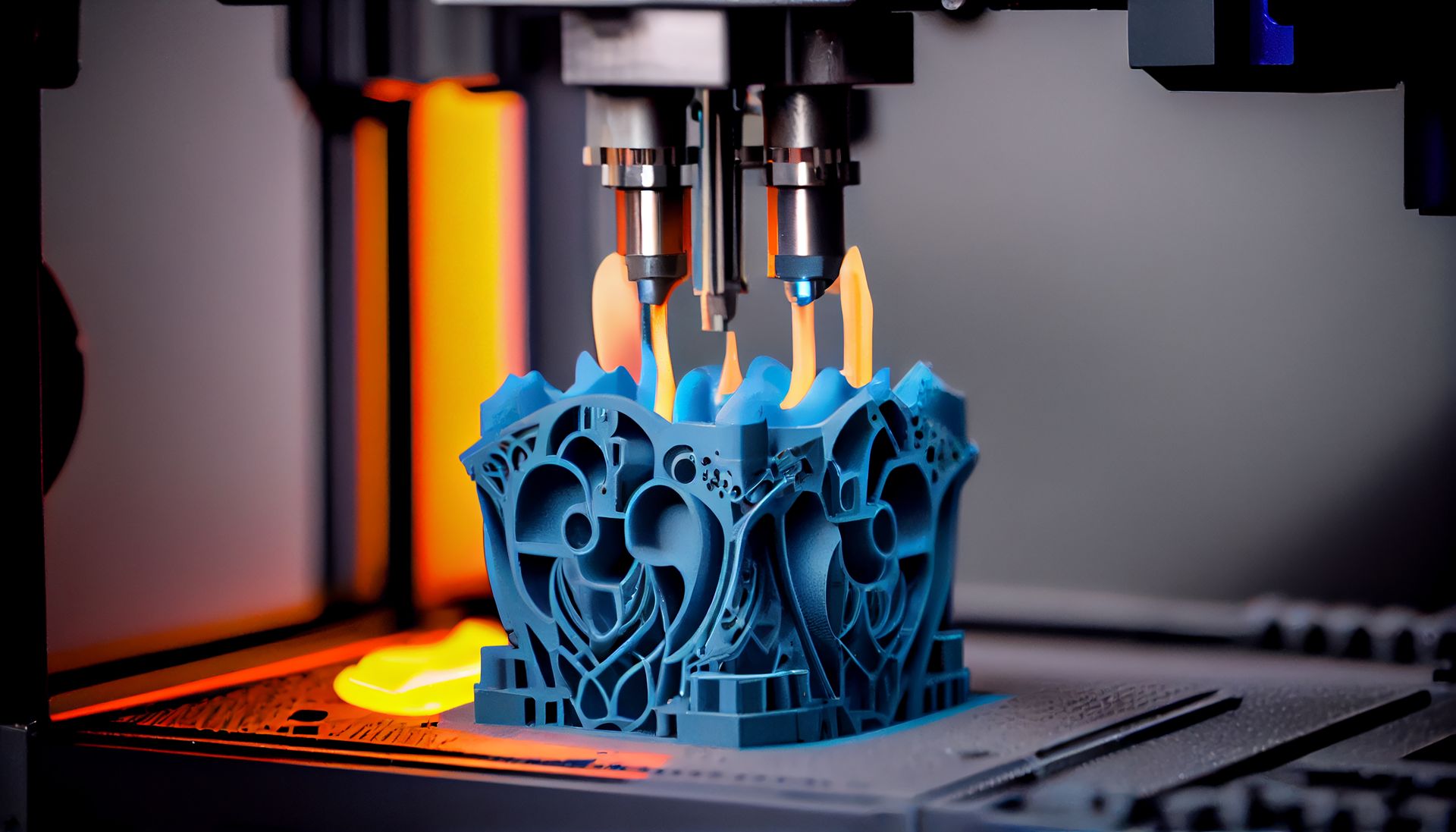

In today’s digital age, where customization is king, the ability to turn an idea into a tangible object is more than just a novel concept—it’s rapidly becoming a standard in various industries. This is where the power of 3D printing resin comes into play, revolutionizing the way we create everything from intricate jewelry to advanced dental prosthetics.

But what makes resin the go-to material for such delicate and precise projects? It’s all about the material’s strength and the quality of the finish it provides, allowing creators to achieve details that were once impossible with traditional manufacturing methods.

Understanding the properties of 3D printing resin and its advantages

3D printing with resin is akin to having an alchemist’s stone for makers. This material is renowned for its robustness, offering a higher level of detail and a smoother finish compared to many other printing technologies.

For those venturing into the world of digital creation, resin stands out for its crisp precision, capable of capturing the most intricate features, which are essential for items such as personalized jewelry or detailed miniatures. Beyond aesthetics, the mechanical properties of these resins can be tailored for specific applications, ensuring that the final product isn’t just a pretty face, but also functionally robust.

Comparing resin printing with other 3D printing technologies

When stacked against its 3D printing counterparts, resin technology shines in its ability to produce models with an exceptionally smooth surface, a trait highly desired by professionals and hobbyists alike. However, it’s not without its drawbacks.

The post-processing steps—such as washing and curing—are essential to solidify and strengthen the final object. Despite this, the extra effort is often considered a worthy trade-off for the high-resolution output that can be achieved, making it a popular choice amongst those who prioritize quality above all else.

The environmental aspects of resin-based 3D printing

With the increasing attention to environmental sustainability, it’s crucial to consider how resin printing aligns with green practices. Forward-thinking manufacturers are now offering biodegradable resins, while initiatives are in place to recycle the liquid resin wastes.

Users are encouraged to minimize their ecological footprint by opting for more eco-conscious materials and maximizing print efficiency to reduce waste. Additionally, the process itself can be more energy-efficient than traditional manufacturing methods, further lowering the carbon footprint associated with resin 3D printing.

Turning concepts into tangible objects with online 3D printing platforms

Imagine being able to bring a sketch to life in just a few clicks. This isn’t a scene from a sci-fi movie but the reality afforded by online 3D printing platforms. These platforms have democratized access to otherwise expensive and complex hardware, allowing anyone with a digital design to see their creations materialize.

The intuitive nature of these services ensures that even novices can navigate the process with ease, making bespoke design more accessible than ever. What’s more, the collaborative nature of these platforms encourages community engagement, where shared creations can be iterated and enhanced by a global pool of users, leading to innovation and improvement in design quality.

Collaboration and innovation in the digital fabrication community

The digital fabrication community is a melting pot of collective genius where ideas and solutions are shared, refined, and celebrated. Online platforms are the virtual workbenches of this community, where members from across the globe can pool their knowledge to push the boundaries of what’s possible.

Success stories abound of collaborative projects that have led to groundbreaking innovations, all thanks to the close-knit fabric of this creative ecosystem. Moreover, for small businesses or independent designers, these platforms offer an invaluable opportunity to prototype rapidly without the overhead of traditional manufacturing processes, bridging the gap between imagination and the market shelf.

Adopting green principles in the 3D printing industry

The pressing need for environmental stewardship has not gone unnoticed in the 3D printing industry. Pioneers in this field are now actively seeking out and developing sustainable materials to lessen their ecological impact. By focusing on the entire lifecycle of the materials used, from production to disposal, the industry is moving towards a more sustainable future.

Additionally, thoughtful design can significantly reduce material usage without compromising structural integrity, further advancing the environmental benefits of this technology. As these practices gain traction, we can hope to see an industry that is as kind to our planet as it is innovative.

The convergence of art, technology, and sustainability paints a bright future for the world of 3D printing, particularly with materials like resin leading the charge. As we embrace these advancements, we step closer to a future where ideas are not limited by physical constraints and where our creations are as limitless as our imaginations.