Among businesses that continuously try to rise out of the competition, automated packaging has emerged as a game-changer for companies across various industries. The advantages it brings are not only tangible but also extend to intangible gains, impacting the company’s efficiency and bottom-line profit.

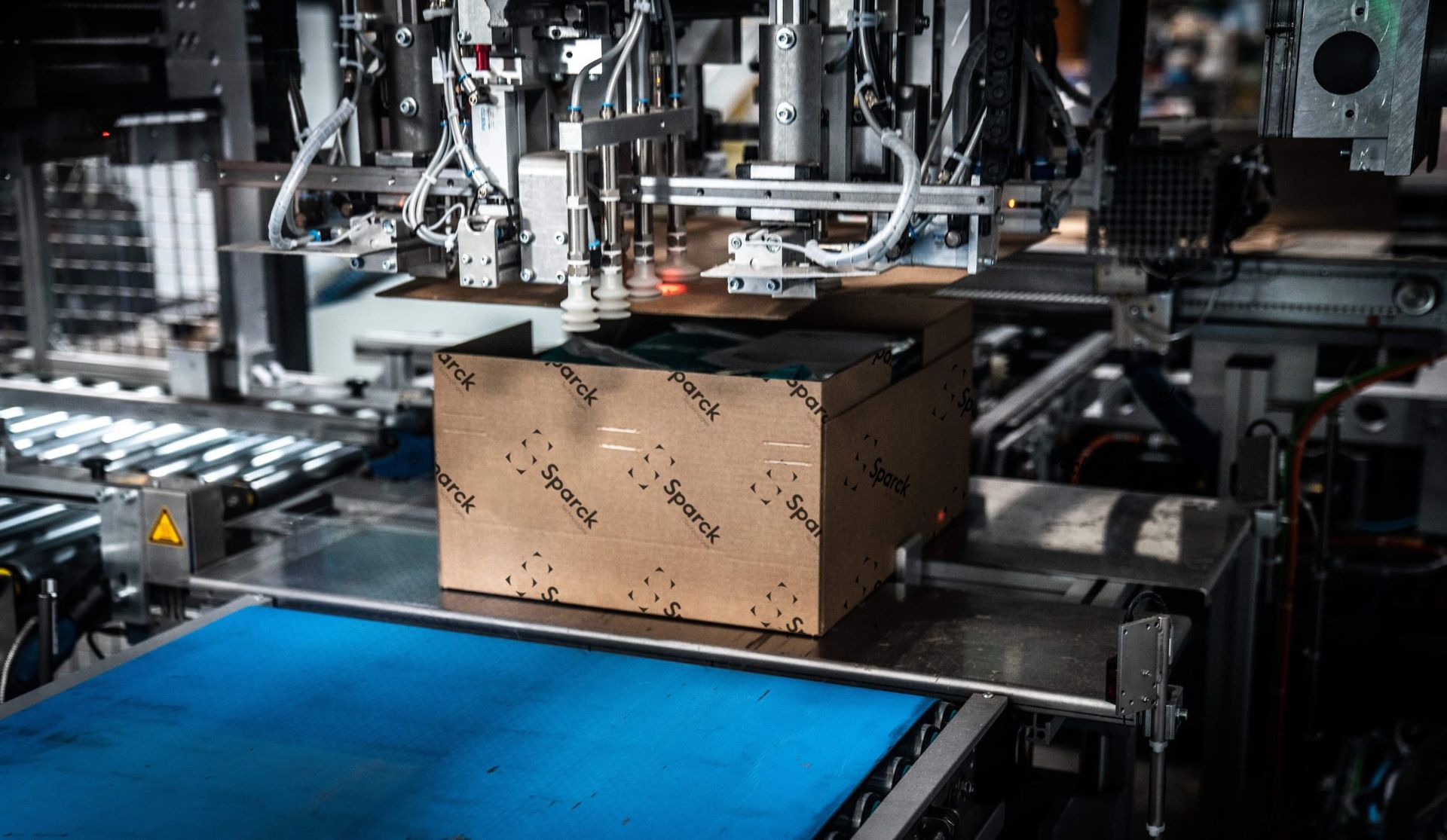

Let’s discover how automated packaging can enhance your business and what Sparck Technologies’ innovative CVP Impack has to offer in that regard.

Diverse applications and tailored solutions of automated packaging

The concept of automated packaging varies depending on the industry and market you operate in. It could mean sealing food in containers or bottling liquids for some, while for others, it might involve bundling and wrapping large sheets of material. This diversity in products necessitates equally diverse automated packaging systems, often tailor-made to suit a company’s specific needs.

In addition to the individual product packaging, there’s often a requirement to box and palletize these products for shipment. When this process is automated, it falls under the category of automated packaging, streamlining the entire preparation process.

Tangible gains

If you wish to understand how automated packaging can positively impact your business in more concrete ways, let’s check out some of them below:

- Reduced risk of repetitive strain injury

- Automation minimizes the risk of repetitive strain injuries, a common concern in manual packing. By removing the need for human intervention in repetitive tasks, automation ensures a safer working environment.

- Elimination of potential bottlenecks

- Human errors in manual packaging can lead to production bottlenecks. Tailored automated machines are designed to seamlessly integrate with the production line, minimizing disruptions and downtime.

- Enhanced production speed

- Automation unlocks the full potential of production machinery, as it no longer needs to accommodate the pace of manual packaging. This leads to improved overall production speeds.

- Elimination of downtime

- Unlike manual labor, machines do not require breaks. This means an automated packaging solution can run 24/7, maximizing productivity.

Intangible advantages

Meanwhile, you might not be able to take rather subtle benefits into account while evaluating the worth of automated packaging operations. Let’s take a look at some of the more indirect gains of automated packaging:

- Boosted staff morale

- Automation frees employees from monotonous, repetitive tasks. With more engaging roles, staff morale improves, leading to increased efficiency and job satisfaction.

- Sales surge from reduced product costs

- While initial capital outlay is required, a thorough cost analysis reveals significant savings in production speed, staffing costs, and other areas. Automated packaging systems ultimately lead to reduced product costs and increased production capacity.

- Enhanced customer service

- Automated packaging significantly reduces the risk of defects and recalls. This, combined with increased production capacity, allows companies to provide better service, leading to more loyal customers and increased profits.

Automated packaging is a transformative tool that brings both visible and hidden benefits to companies. From streamlining operations to improving employee satisfaction and customer service, the advantages are far-reaching. Embracing automated packaging is not just an investment in efficiency; it’s an investment in the future success of your business.

Nevertheless, as well as whether you make this investment or not, it is quite important to consider how you make this investment. The direction you take while enhancing your business’ packaging systems is one that has long-term implications for your operations, therefore it’s a topic to be cautious about. Considering the need for innovation and efficiency in automated packaging CVP Impack is a tool that has been standing out among its competitors. Let’s check out Sparck Technologies’ automated packaging solution in detail and see what benefits it can offer to your business.

CVP Impack checks all the boxes

As mentioned, when it comes to automated packaging solutions, the CVP Impack from Sparck Technologies stands out for its innovation and efficiency. This state-of-the-art system has been meticulously designed to address the diverse needs of businesses across various industries.

Efficiency

The CVP Impack is not just a machine; it’s a revolution in packaging. With the capability to process up to an impressive 500 boxes per hour, it’s a powerhouse of productivity. Imagine the time and resources saved when 15 manual packaging stations are seamlessly replaced by this automated marvel.

Adaptability

One of the standout features of the CVP Impack is its adaptability. Whether you’re dealing with hard or soft, single or multi-item orders, this system handles them all with equal precision. It’s a fit-to-size auto-packer, meaning each order is processed in a seamless flow, from measurement to labeling.

Box volume reduction

The CVP Impack doesn’t just save time; it’s also environmentally conscious. By reducing box volume by up to 50%, it minimizes corrugate spend and virtually eliminates the need for void fill. This translates to significant cost savings and a smaller ecological footprint.

Personalized branding

If you own a business that is trying to make itself seen, branding is of paramount importance. The CVP Impack offers personalized printing, allowing you to tailor messages, logos, and branding for each package. With high print quality at up to 360 dpi, your packages leave a lasting impression.

Comprehensive data

In the world of automated packaging, knowledge is power. The CVP Impack provides detailed and timely performance data through a suite of data products. This allows you to not only monitor but also optimize your automated packaging operations for maximum efficiency.

Reliable support

Sparck Technologies doesn’t just deliver a product; they offer a partnership. With a commitment to unparalleled customer support, they ensure that your experience with the CVP Impack is nothing short of exceptional. From remote assistance to on-site services, they have you covered.

Final thoughts

As efficiency is one of the key aspects that will determine the future of your business, if not the most,, the CVP Impack can potentially be your winning move. Its focus on efficiency, precision, and dependability offers a distinct advantage that we don’t often witness in the market.

It appears that Sparck Technologies presents not just a product, but a forward-thinking solution. From our perspective, exploring the potential it holds for the future of your packaging process can really be a step worth taking.

Featured image credit: Sparck Technologies