We explain the popular term digital twin in this article and answer questions like: What is it, its advantages and areas of use.

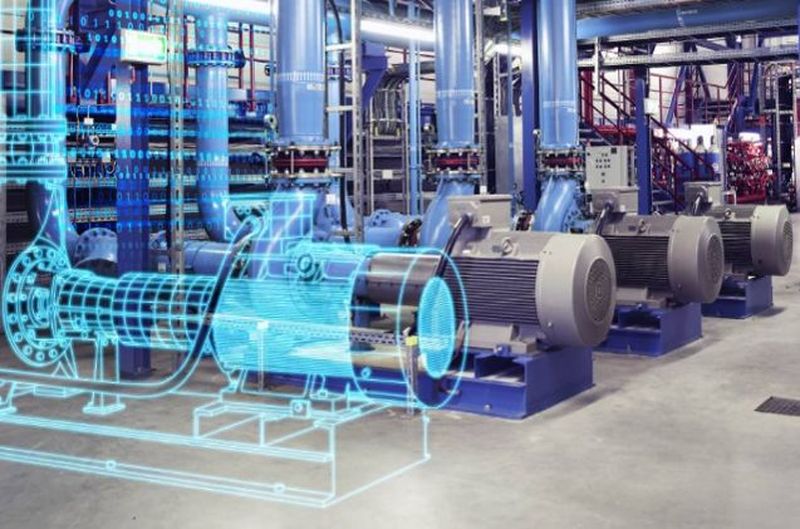

“Digital twin”, the term currently used in the technological world to refer to a virtual replica of a product, service, or process that simulates the behavior of its corresponding product, service, or physical process, to monitor it, analyze its reaction to certain situations and improve its performance and efficiency. Thus, thanks to these new systems, possible errors can be anticipated, obtaining better production ratios and in a faster way. Moinsa, an expert in technology and intralogistics, explains all about this new form of disruptive technology that is so much in vogue today.

What is a Digital Twin?

Over the years, and more and more, Industry 4.0 is growing and growing, industrial integration and automation in all manufacturing processes and machine learning systems are here to stay, and are becoming increasingly necessary in any organization. In addition, in recent years the figure of the digital twin has emerged, whose advantages Moinsa defines:

- Exhaustive analysis of information: Although the origin of the implementation of digital twins has been applied to industrial and production environments, the union of the physical and virtual worlds through them, enables access to information. This, combined with ‘big data solutions, the internet of things, or artificial intelligence, allows a rigorous control of systems and processes, thus avoiding risks, and knowing and preventing equipment activity/inactivity times.

- Corrections and deviations from the management model: Knowing exhaustively the available information allows establishing corrections and being aware of deviations from the management model, thus implementing a series of measures that favor risk reduction.

- Real-time data and information: By having a virtual copy of the systems, and relying on sensors and IoT, it is possible to have real-time access to critical data for the organization and establish control measures to ensure the integrity of the system at all times.

On the other hand, the implementation of a digital twin is as follows: This involves the complete digitization of all existing infrastructures, objects, or services that support the information to be managed. It should start with the digitization of these, even layers of information related to critical facilities can be added (electrical installations, air conditioning, gas installations, etc.), which will allow adding knowledge related to other aspects such as energy efficiency of buildings.

In Mona’s Technology area, they make the creation of Digital Twins a reality, applying the latest technologies, always based on quality and experience.