3D printing has a huge potential, it is surprising in many aspects and there are even those who make a living with it. However, it can be discouraging when we come face to face with the reality that it takes hours and sometimes days to print something. Now researchers are proposing a new method that they say is 10 to 50 times faster than previous methods.

A new 3D printing method developed

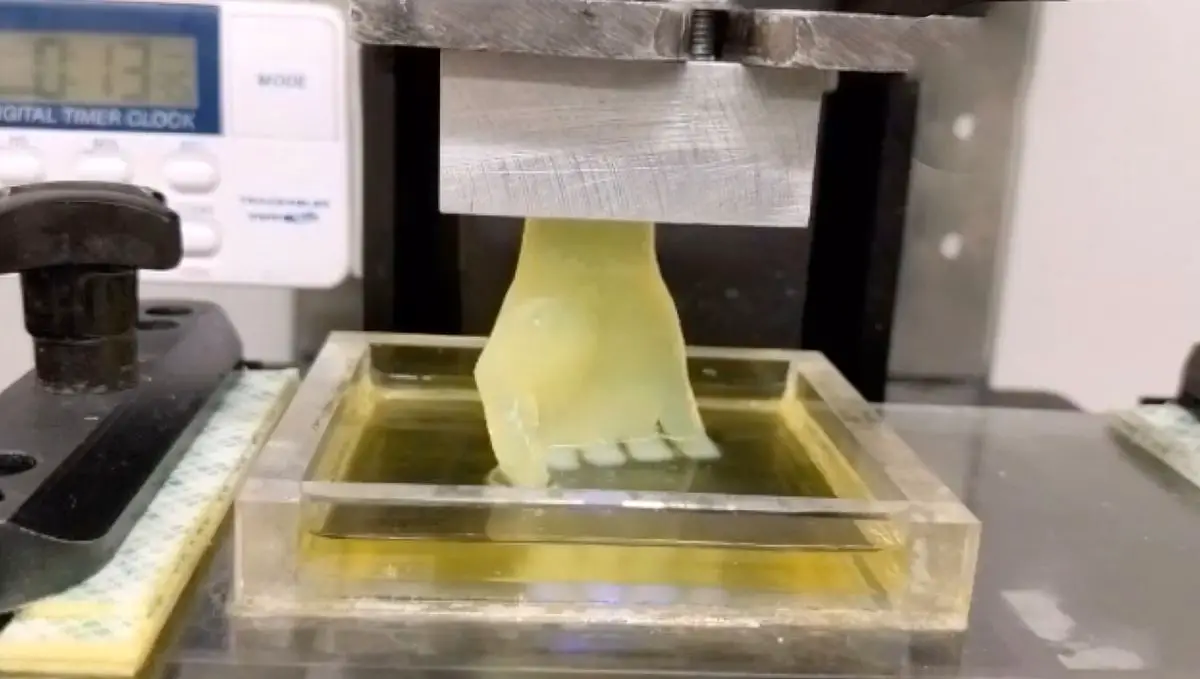

The research has been carried out by a team from the University at Buffalo and they have published their results in the journal Advanced Healthcare Materials. It is a method with which, for example, they manage to print a hand from a flexible material in just 19 minutes. To put this in context, traditional 3D printing methods need at least 6 hours of work.

Stereolithography

That’s the keyword, stereolithography. This is the 3D printing method they have used and is based on using lasers to harden a liquid resin and hydrogels. Hydrogels absorb large amounts of water without dissolving and are typically used for contact lenses for example. It is not an entirely new printing method, but here it has been adapted to make it faster and ideal for flexible materials. It is a technology not far removed from light printing.

The technique essentially uses lasers to harden the liquid material of which the final object is composed. In this way, as the liquid solidifies, it gives shape to the object to be printed. This is how, for example, the hand of the liquid container appears in the following video:

According to them, their method is 10 to 50 times faster than others previously used and standard in the industry. It also works with large objects, which are generally more complicated to make due to the size of traditional 3D printers.

They believe their method is especially interesting when it comes to printing artificial organs. Artificial organs are usually made of flexible materials to mimic natural ones and often need to be adapted in form and function to each patient. Hence, it is interesting to use 3D printers to create them to one’s preference. They say their method can print cells with embedded networks of blood vessels. Something that would be of great help for the construction of human tissue and organs in the future.

Whether this is going to be the future for artificial organ printing time will tell. They are not the only ones with an eye on it, we also have the creator of SegWay who sees the manufacture of human organs viable in ten years. In Japan, they are already experimenting with it, growing human organs in animals.