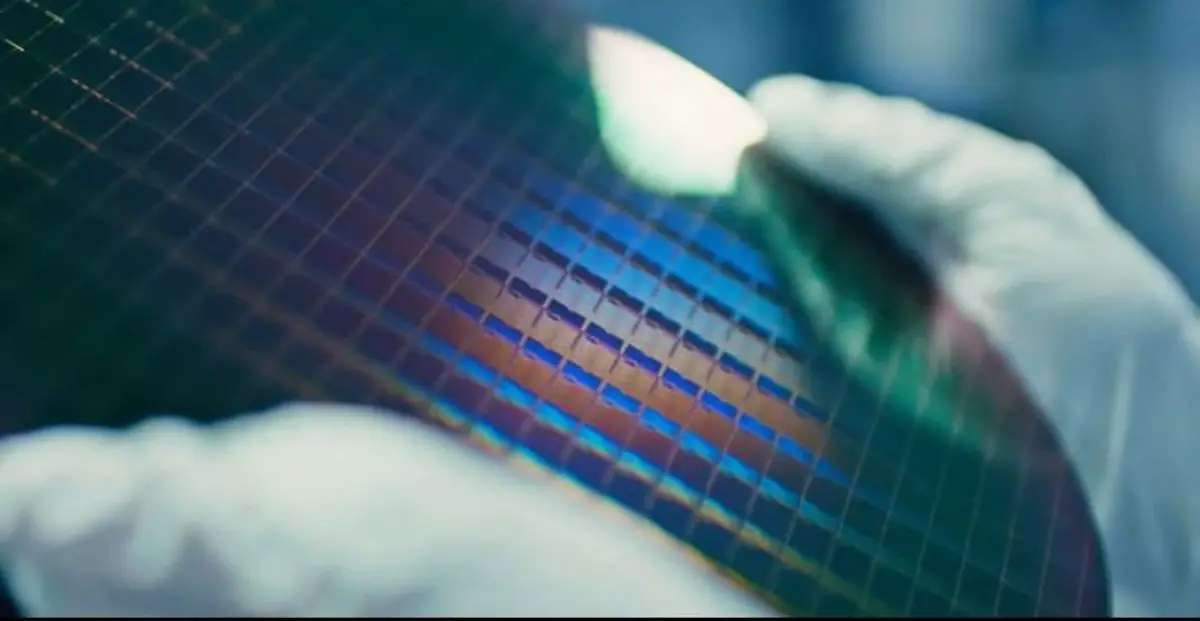

Intel announces increased wafer production capacity for 10nm. The company announced this morning that it has expanded its wafer fabrication capacity to a 10nm manufacturing process, thus overcoming all of the company’s concerns about this manufacturing process, which has proven to be very robust in the Intel Tiger Lake laptop product range.

Intel will increase 10nm wafer production capacity for Tiger Lake-H and Alder Lake-S processors

This expansion will also allow the market to be supplied next quarter with the high-performance Tiger Lake-H laptop processors and, by the end of the same year, the highly anticipated Alder Lake-S processors.

In response to incredible customer demand, Intel has doubled its combined 14nm and 10nm manufacturing capacity in recent years. To do this, the company found innovative ways to deliver more performance within existing capacity through performance improvement projects and significant investments in capacity expansion. This video chronicles that journey, which even included the reuse of existing laboratory and office space for manufacturing.

“In the last three years, we have doubled our wafer volume capacity, and that was a significant investment. We continue to invest in factory capacity to ensure that we can keep up with the growing needs of our customers,” said Keyvan Esfarjani, senior vice president and general manager of Manufacturing and Operations at Intel. The company has also accelerated its new 10nm manufacturing process this year. Intel currently manufactures 10nm products in high volumes at its sites in Oregon and Arizona in the U.S. and its site in Israel.

In 2020, Intel introduced an expanding 10nm product line, including the 11th generation Intel Core processors and the Intel Atom P5900, an SoC for wireless base stations. In addition, the company introduced 10nm Superfin technology, which enables the largest single internode upgrade in Intel’s history and delivers performance improvements compared to a full node transition.

“The progress of 10nm is going quite well. We have three high-volume factories that are moving full steam ahead to see how we can do more, better and faster, and still, support our customers.”